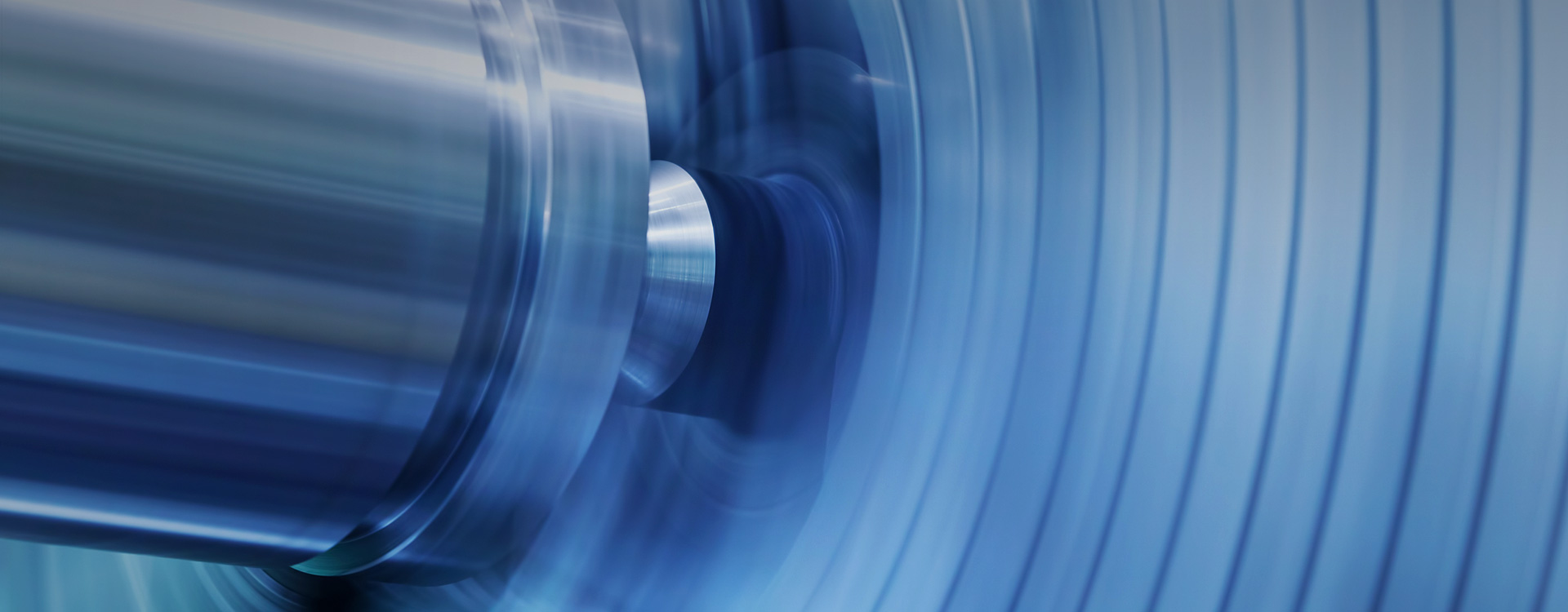

MICRO GAS TURBINE

Gas turbines, known as “jewel in the crown” in the equipment manufacturing industry, are not only the heart of the energy system, but also the core power of aircraft, ships and military systems.

Working principle

Micro gas turbine cycle is a Brayton cycle. The filtered air enters the compressor for compression; the compressed high-pressure air enters the combustor and mixed with the fuel in the combustor then hot gas with high-pressure flows into the turbine, which produces work and drives the generator to convert mechanical energy to electricity. The exhausted high-temperature gas can be used in the waste heat recovery devices to produce useful heat and energy.

Features of Micro Gas Turbine

Micro-gas turbines have become the core power equipment in gas distributed energy system.

-

Good fuel compatibility

Multi- fuel compatible, such as natural gas, methane, biomass gas, landfill gas, coke oven gas, blast furnace gas, coalbed methane, petroleum associated gas, diesel, heavy oil, gasoline, and kerosene etc..

-

High reliability

Long useful life and long service free period

-

Environmental friendly

Low emission. NOX emission is lower than 9 ppm. Noise level is lower than70 dB.

-

Convenient operation

Small size, light weight, highly mobile;

good scalability;

remoted monitoring, automatic operation.

Advantages of Micro gas turbine

-

High cost performance

Independent research and development, highly cost-effective, short purchase cycle, low operation and maintenance costs.

-

Customized product service

With strong personalized and customized service capability, ENN Power can make a quick response based on customers’ demands to carry out customized service, with a normal development cycle of 6 months.

-

Adjustable hot spot ratio

With strong personalized and customized development capability, ENN Power can make a quick response based on customers’ demands to carry out customized development, with a normal development cycle of 6 months.