Distributed energy solution for industries &industrial parks

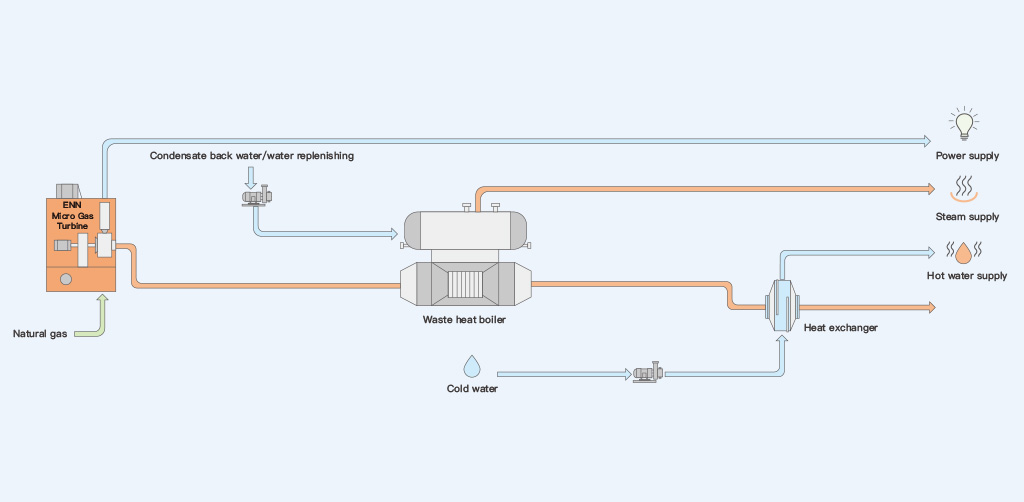

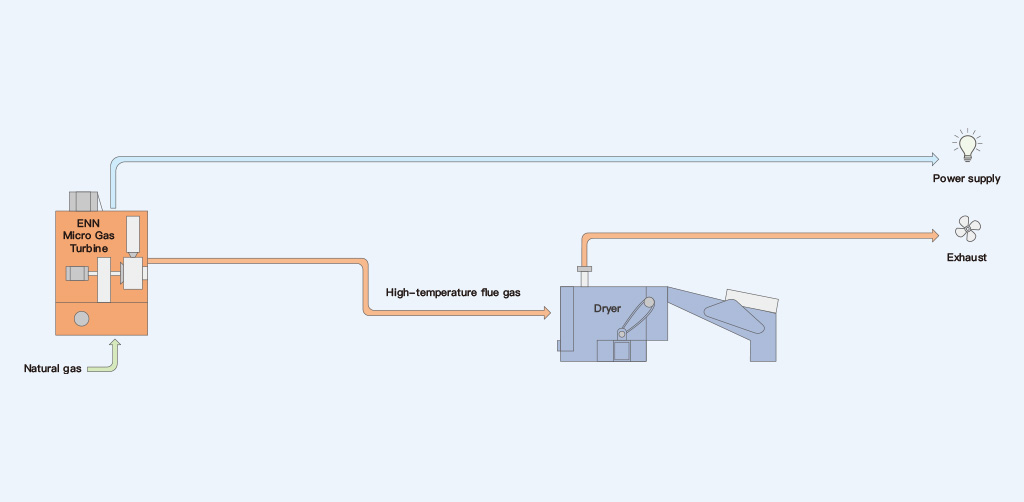

Industries and industry parks require a large amount of energy of different forms, such as electricity and heat that use gas distributed energy supply. When the gas turbine generates electricity, the high-temperature exhaust gas passes the waste heat equipment to produce steam or hot water for customers, and to meet users’ drying demand. Compared with separated production of electricity and heat, it effectively avoids heat loss caused by pure heating or power generation, thus greatly improving energy utilization efficiency. Because it is close to users, it can match energy consumption needs of production and reduce electricity transmission losses. It can reduce the energy cost and emissions. At the same time, for industrial users with insufficient capacitor capacity, the grid capacity can be expanded which has good social, economic and environmental benefits.

Working Principle

Application Industry

-

Pharmaceuticals and detergent

-

ceramics and metal manufacturing

-

rubber and plastic products

Application cases -

paper-making, printing and wood processing

-

general machinery manufacturing

-

chemical, metal products

Application cases -

leather, fur and shoe-making

-

textile, printing, dyeing, and chemical fiber

Application cases -

foods, liquor and beverage processing,

Success Stories